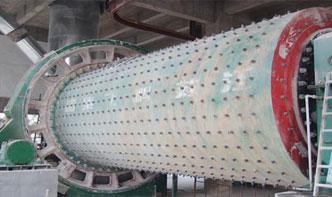

Modern batch ball mill For Spectacular Efficiency ...

High Efficient Soda Feldspar Quartz Ceramic Clay Batch Dry Ball Mill for Sale. 9, / Set. 1 Set (Min. Order ) 14 YRS CN. Supplier. (2) | Contact Supplier. 1/3. China Small Type Stone Grinding machine Ceramic Batch Ball Mill for Silica. 8,78, / Set. Sets (Min. Order) 5 YRS CN. Supplier. (1) | Contact Supplier. 1/6. Mining Factory Small Wet Batch Ball Mill .